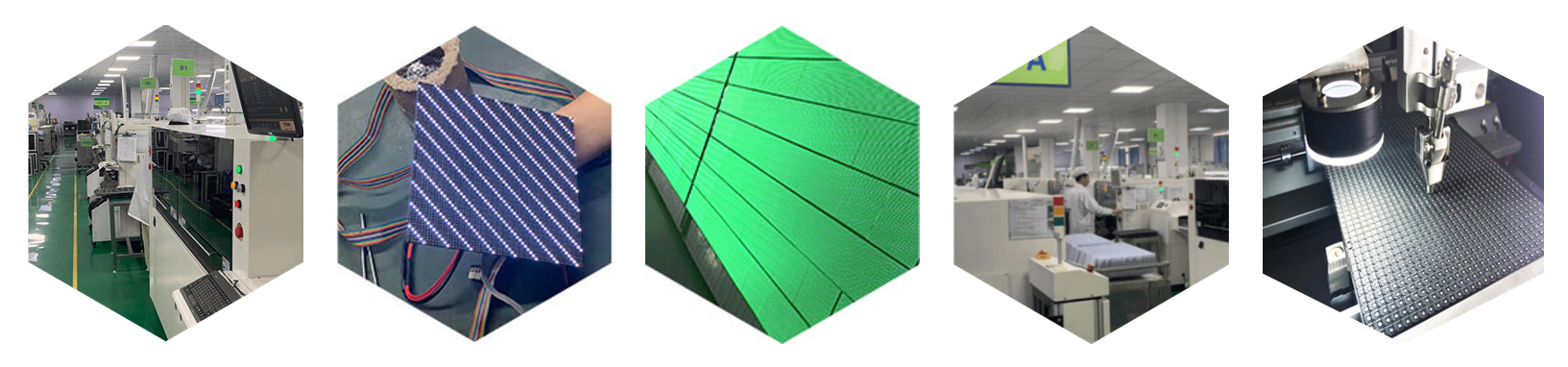

Production Process

Conformal paint and strict aging testing to ensure the high quality of the LED display.

In the fast-paced world of technology, LED displays are becoming increasingly popular due to their vibrant colors, energy efficiency, and durability. These innovative displays are revolutionizing advertising, signage and visual communications across industries. However, behind the seamless visual experience is a meticulous production process that incorporates cutting-edge technology to ensure the top quality of LED displays.

A key link in the production of LED display screens is the application of conformal paint. This special coating is water-, dust- and moisture-resistant, protecting the display from environmental factors that could affect its performance. Water resistance protects the display from rain, splashes, or any moisture-related mishaps that may occur during use. Dustproofing prevents debris build-up, ensuring the display maintains clarity even in dusty environments. Finally, moisture protection protects the display’s electronic components, extending its lifespan and reliability. By using conformal coatings, manufacturers can ensure that their LED displays can withstand challenging conditions and provide a superior visual experience in any environment.

Another key link in LED display production is the lamp bead packaging process. A lamp bead is a single component in an LED display that emits light. Careful packaging of these lamps ensures their stability, efficiency and prevents external damage. The process involves packaging the chip, connecting it to a power source and sealing it with resin or epoxy. Lamp bead packaging plays an important role in the overall performance, color accuracy, and lifespan of the LED display. Manufacturers utilize advanced technology to ensure precise packaging, meticulous soldering, and reliable connections to produce high-quality displays with stunning visuals and exceptional durability.

In order to maintain the high standards set during the LED display production process, strict aging testing is performed. This test simulates the display's performance over an extended period of time, ensuring it can withstand the demands of continuous use while minimizing performance degradation. The burn-in test inspection process involves subjecting the display to specific conditions, such as high temperatures and continuous operation for long periods of time. This process ensures that any weaknesses or potential faults are detected, allowing manufacturers to correct and improve the display's performance before it is released on the market. By implementing rigorous burn-in testing procedures, manufacturers can assure customers of the durability, reliability and consistent performance of their displays.

The production process of LED display screens is a carefully orchestrated symphony of precision, innovation and quality control. By combining conformal coating, lamp bead encapsulation and aging testing, manufacturers can achieve superior results in durability, performance and longevity. These measures not only ensure that the LED display can withstand harsh environmental conditions, but also provide excellent visual quality. Therefore, businesses across industries can rely on these displays to engage their audiences and communicate their messages effectively.

we understand the importance of a perfect LED display production process. Our team of experts and cutting-edge facilities enable us to manufacture top-quality LED displays that exceed industry standards. We prioritize the use of conformal coating, meticulous lamp bead packaging, and strict aging testing to provide displays that meet diverse application needs. With our commitment to quality and innovation, Bescan Technologies is your trusted partner for state-of-the-art LED displays.