Production Floor Quality Control: Ensuring Excellence

In today's highly competitive market, maintaining excellent quality standards has become an important aspect of every industry. Bescan is a striking example of a company that fully recognizes the importance of quality control. As a leading manufacturer, Bescan is committed to providing products that not only meet but exceed customer expectations. To this end, the company fully implements the ISO9001 quality system and strictly implements three-stage inspection during the production process.

Implementing an ISO9001 quality system demonstrates Bescan's commitment to providing excellent products. This internationally recognized standard sets out guidelines to ensure that organizations consistently meet customer requirements and continuously improve their quality management systems. By adhering to this system, Bescan demonstrates its commitment to excellence at every stage of production. From raw material procurement to final product assembly, quality control measures are taken to maintain consistency and reliability.

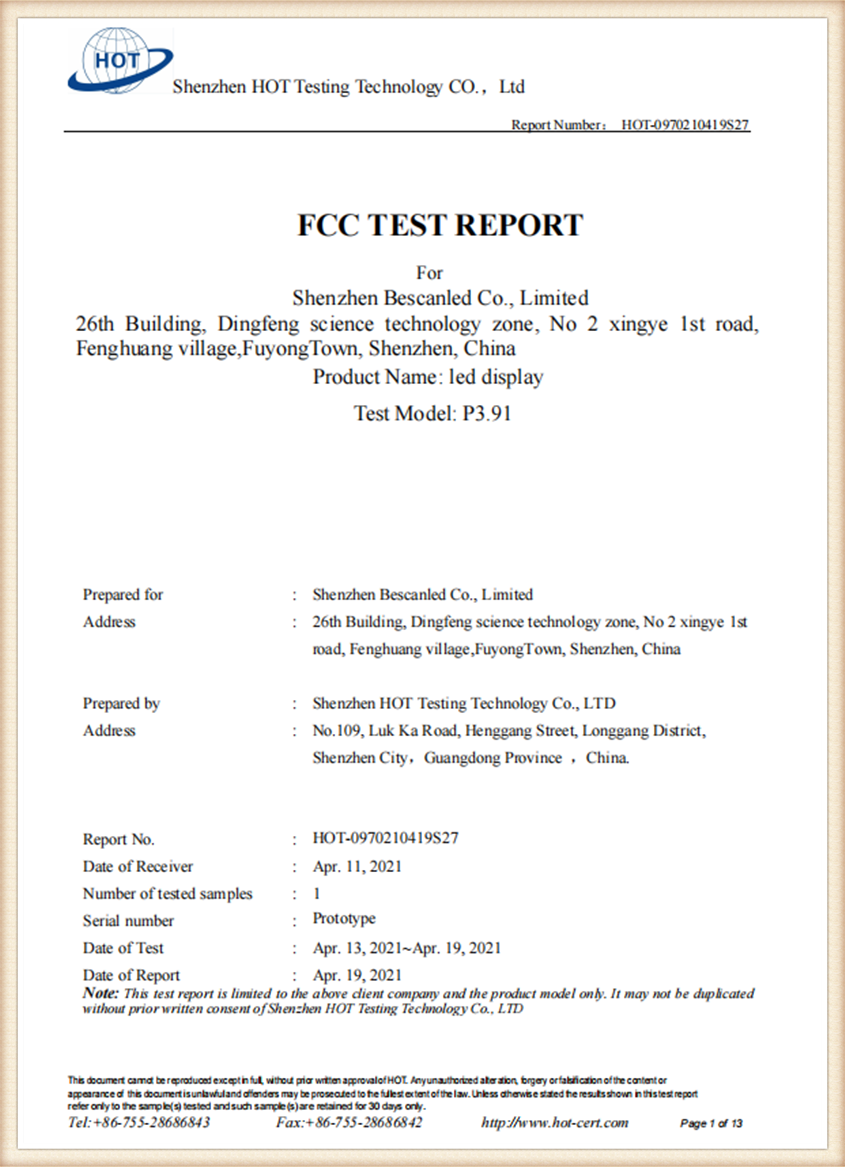

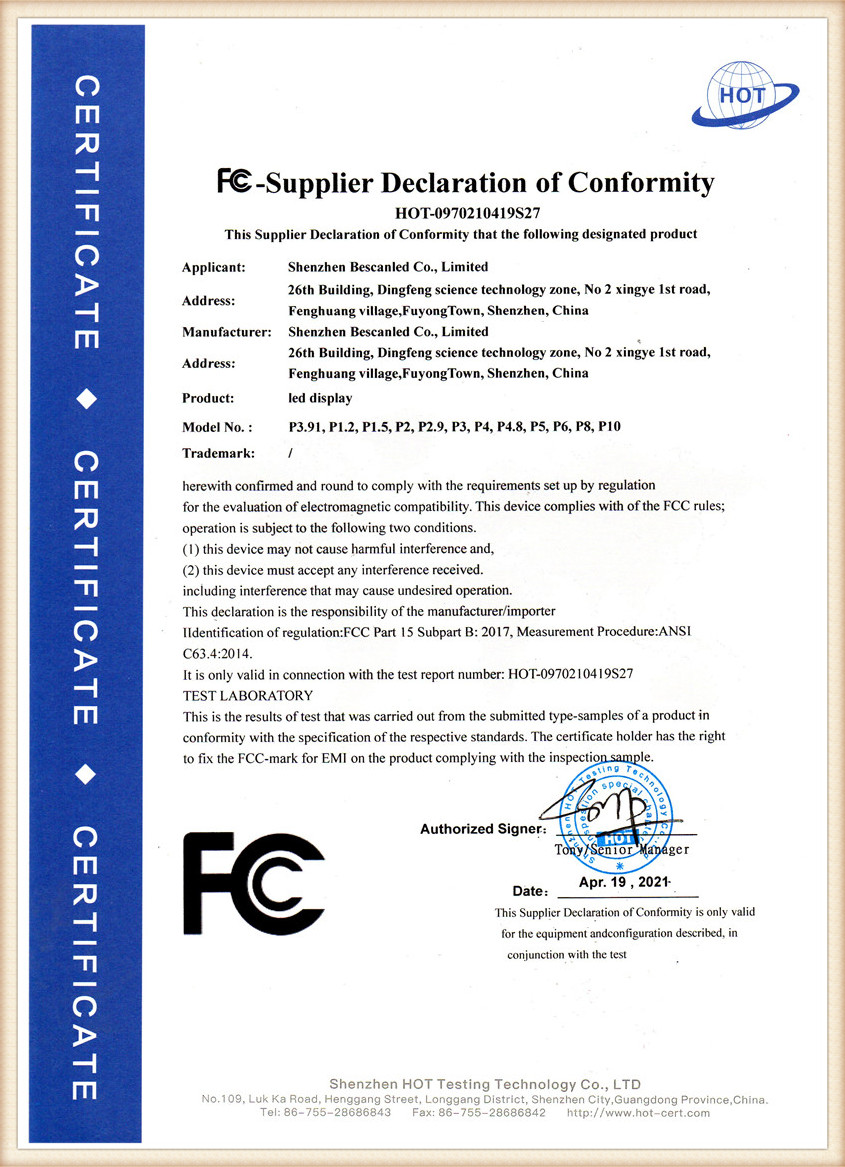

FCC Test Report

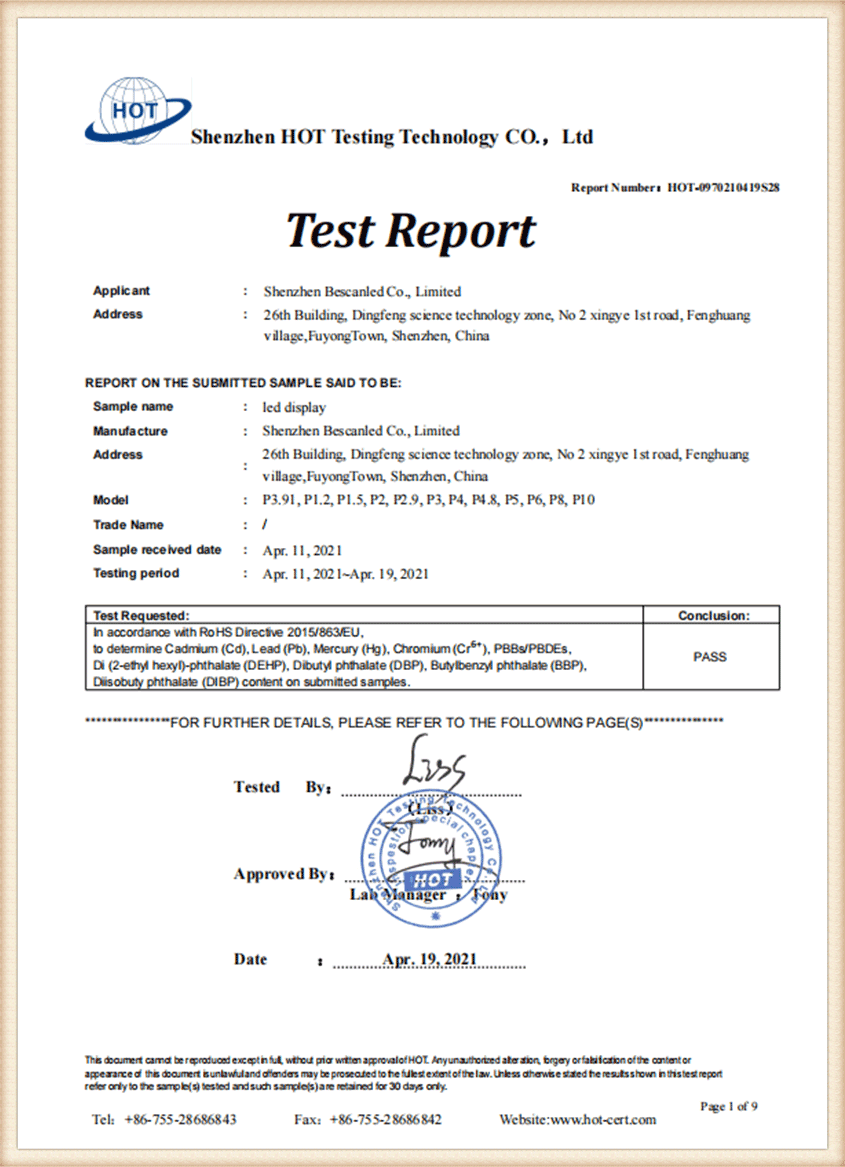

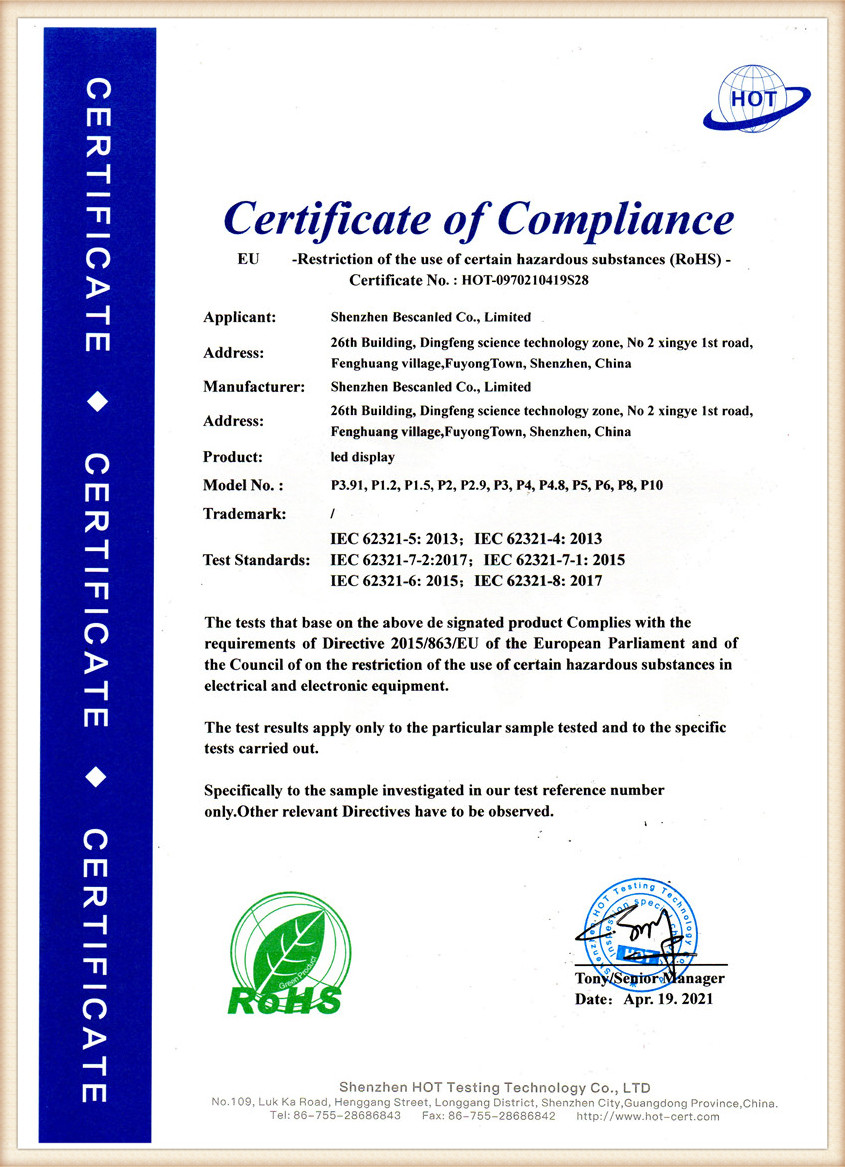

ROHS Test Report

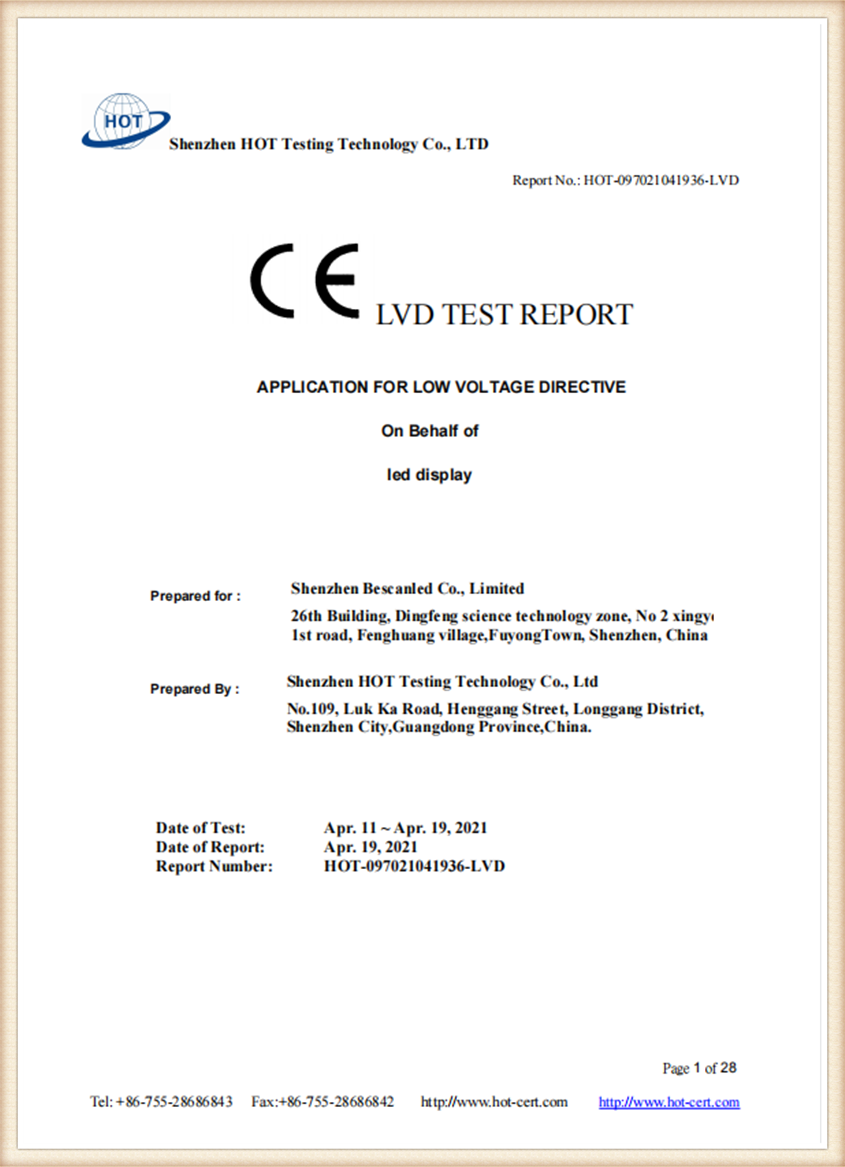

CE LVD Test Report

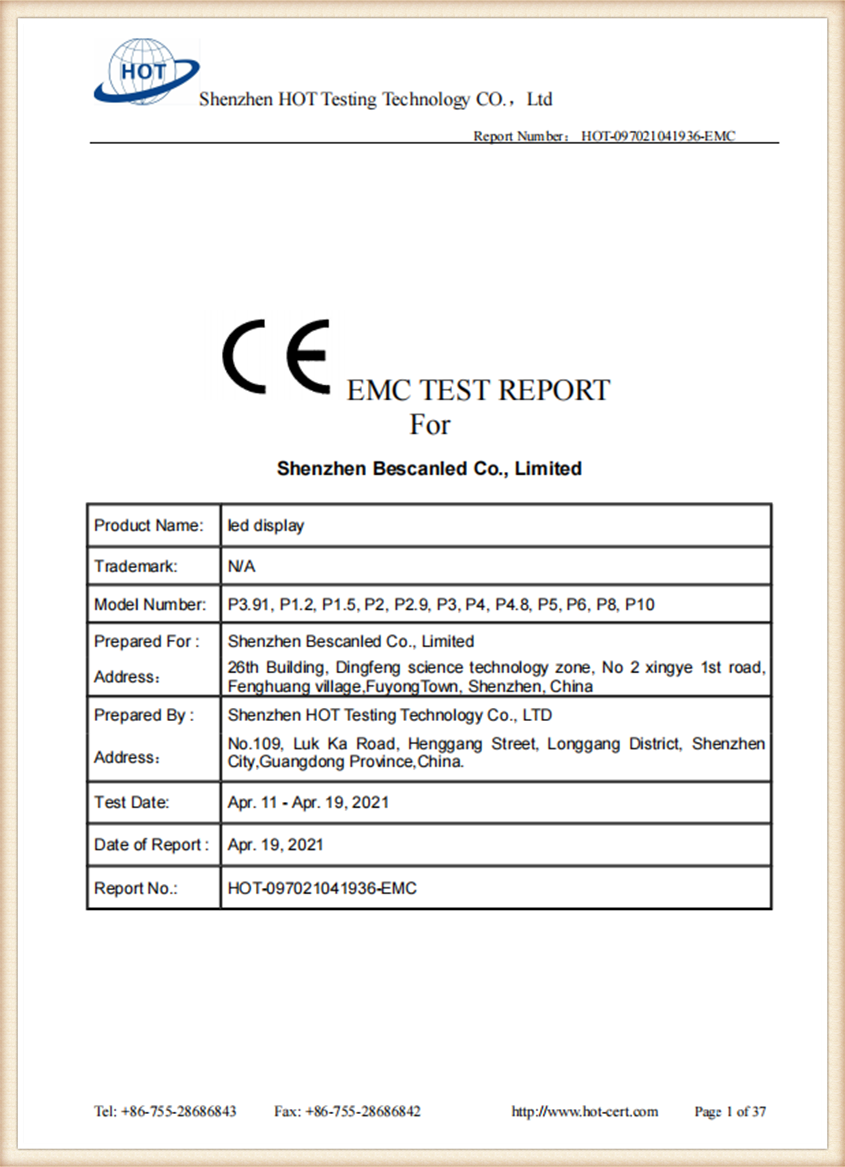

CE EMC Test Report

In addition to the ISO9001 quality system, Bescan's production process includes three key inspections that are closely integrated to ensure the highest quality output. The first inspection is carried out at the initial stage to check the quality, authenticity and compliance of raw materials with specifications. This step ensures that the foundation of each product is of the highest standards, contributing to overall excellence. The second inspection occurs during the production phase, where quality control experts carefully monitor and evaluate each step of the manufacturing process. This stage prevents any deviations from approved standards and resolves any issues immediately to prevent defects from developing further. Finally, a final inspection is performed to verify that the finished product meets the strict quality standards set by Bescan. This systematic approach ensures that only products that meet the highest quality standards reach customers.

Bescan's commitment to quality control goes beyond inspections. The company's culture of continuous improvement ensures that every employee is committed to excellence. We conduct regular training programs and seminars to equip production personnel with the knowledge and skills needed to detect and prevent quality issues. This proactive approach ensures potential issues are identified and resolved early, streamlining production processes and improving product quality.

CE

ROHS

FCC

In short, quality control plays an important role in Bescan's production workshop. By fully implementing the ISO9001 quality system and employing three meticulous inspections, Bescan ensures that its products always meet and exceed customer expectations. This commitment to quality control, combined with a culture of continuous improvement, enables Bescan to maintain its reputation as a manufacturer of superior products. With Bescan, customers can rest easy knowing that the products they receive have been rigorously vetted to deliver the highest quality and reliability.